All of our machinery is available

- with and without vacuum technology

- explosion-proof (ATEX)

- with state of the art drive-, control- and communication technologies

- with volumetric or gravimetric dosing systems

- with tele diagnostic system for rapid diagnostic tests and support independent of the location of the machine (via ISDN, GSM, analog modem or the internet)

No limits to discharge rate and design!

ADM equipment convinces lasting

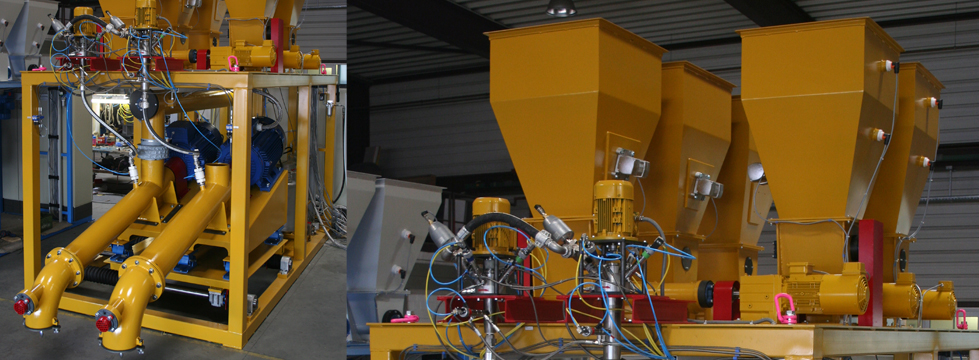

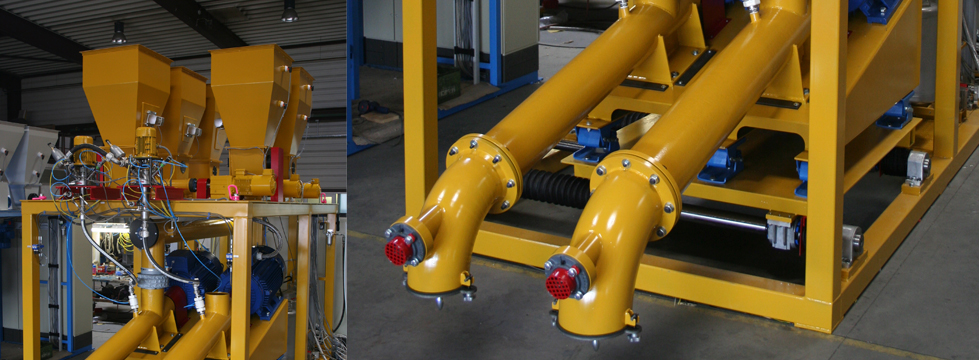

The secret of our machinery is the combination of robustness and precision. In every detail there is a blend of reliability, safety and proven quality with individual flexibility and finest technologies. State of the art sciences and techniques are built into every single ADM machine which makes the result long lasting and our machinery durable and resilient. Numerous machines, having worked in both single- and double shifts for more than 30 years and still going strong, prove this.

All around flexible

The flexibility of our machine modules allows us to meet your demands, for polymer concrete as well as for mineral castings, solid surface, engineered stone, secondary raw materials, noninflammable and non-toxic insulation foam or your individual products. Every machine is unique, manufactured precisely according to your needs.

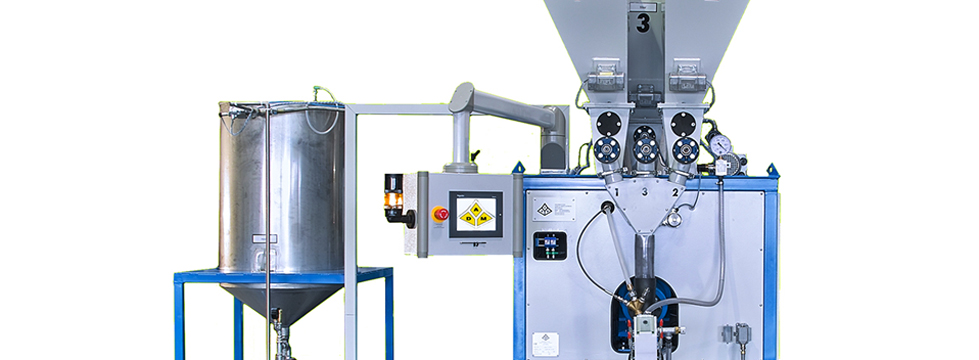

Innovative vacuum technology with new technology concept:

- gentle mixing- and evacuation processes

- discharge rate variable up to three times without exchange of mixing tools

- raised reliability within the production process

- production of low- and very high viscous, evacuated casting compounds within the same mixing unit

- high abrasion resistance of the mixing tools, even with very hard filler materials and heavily filled casting compounds

- both very low and high density casting compound fabricable